Description

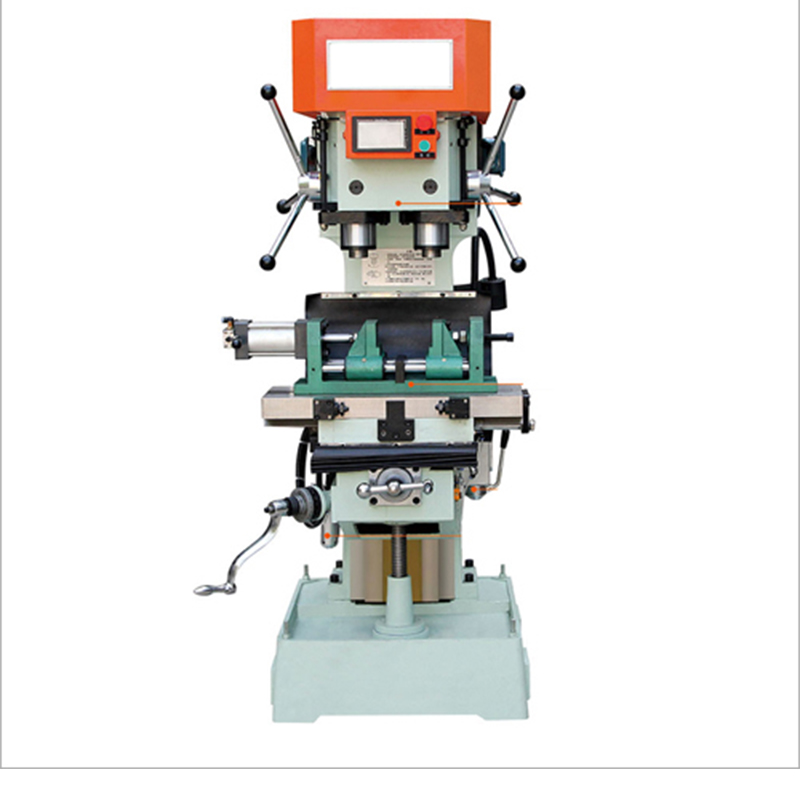

A double spindle drilling and tapping machine is a versatile tool used in various industries for drilling and tapping holes in materials. It is designed to have two spindles, allowing simultaneous drilling and tapping operations, which helps to increase efficiency and productivity. The machine is typically equipped with adjustable heads or fixtures that can accommodate different hole sizes and spacing requirements. It may also have multiple speed settings and feed rates to accommodate various materials and hole depths. The double spindle drilling and tapping machine is commonly used in industries such as automotive, aerospace, and manufacturing, where precision drilling and tapping operations are required. It offers reliable and accurate drilling and tapping capabilities, reducing the need for manual labor and improving overall production efficiency.